As a part of our sustainable development considering the energy starving future re-use and re-cycling is the need of hour. To save thermal energy we have developed Air-to-Air Heat Recovery Unit.

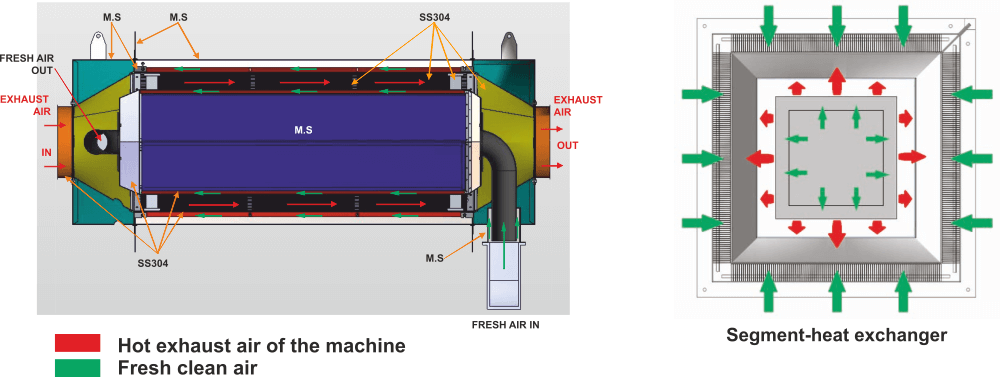

Working Principle

- The hot exhaust air from the machine passes through HRU and heats up the segment heat exchanger

- Clean fresh air passes through the segments in counter flow. The large exchanger surface of the segments results in a maximum preheating of the fresh air

- The heated up fresh air is directly passing into the stenter compartment

- Clean fresh air passes through segments of heat exchanger (no obstacles in hot air passage) that leads to minimum cleaning requirements & efforts

- No reinforcement / replacement of exhaust fan required even at the time of retrofitting

- Can be easily retrofitted into the existing exhaust ducts – no large scale re-ducting required

- Completely pre-assembled and ready for installation

- Heated-up fresh air directly fed into the stenter compartment that leads to virtually no heat radiation loss

- 50 mm thick high density insulation is provided inside the HRU to prevent heat loss even when exhaust air is passing through HRU

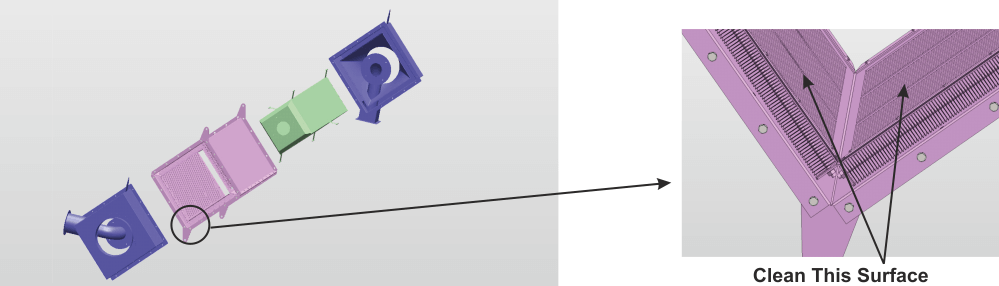

- Due to its unique & modular design, cleaning is easy & required at long interval

- For cleaning of HRU, 2 side covers & centre portion needs to be removed as shown in photo

- Saving through HRU normally depends on exhaust air temperature and exhaust air volume; higher the exhaust air temperature and exhaust air volume, higher the saving

- Payback period from 12 to 36 months is possible depending on the fuel used and saving

- Helping in reducing Global Warming; saving in carbon footprints

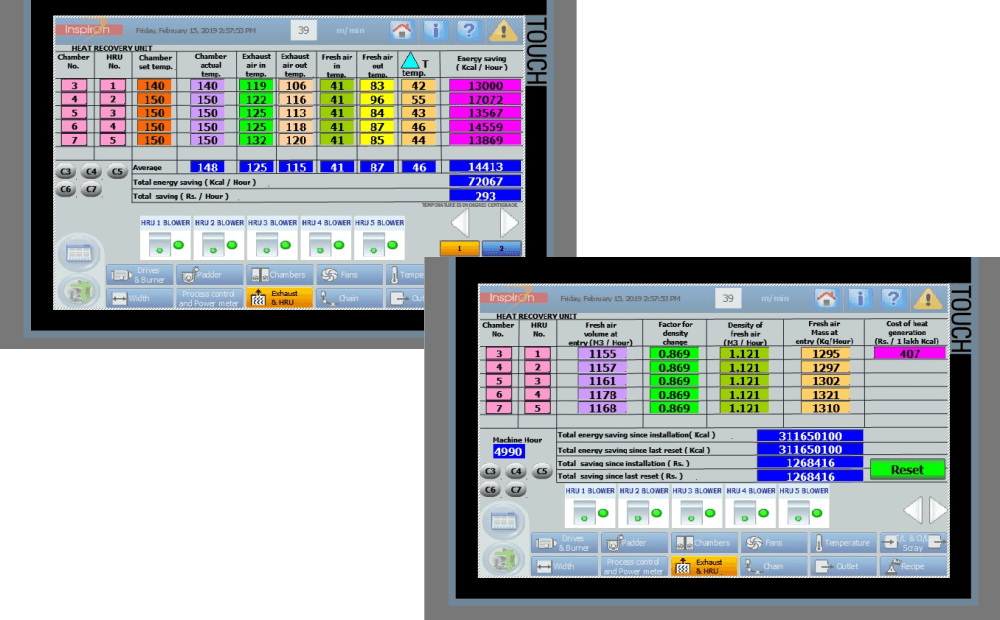

- Monitoring of saving is possible from HMI

Features / USPs

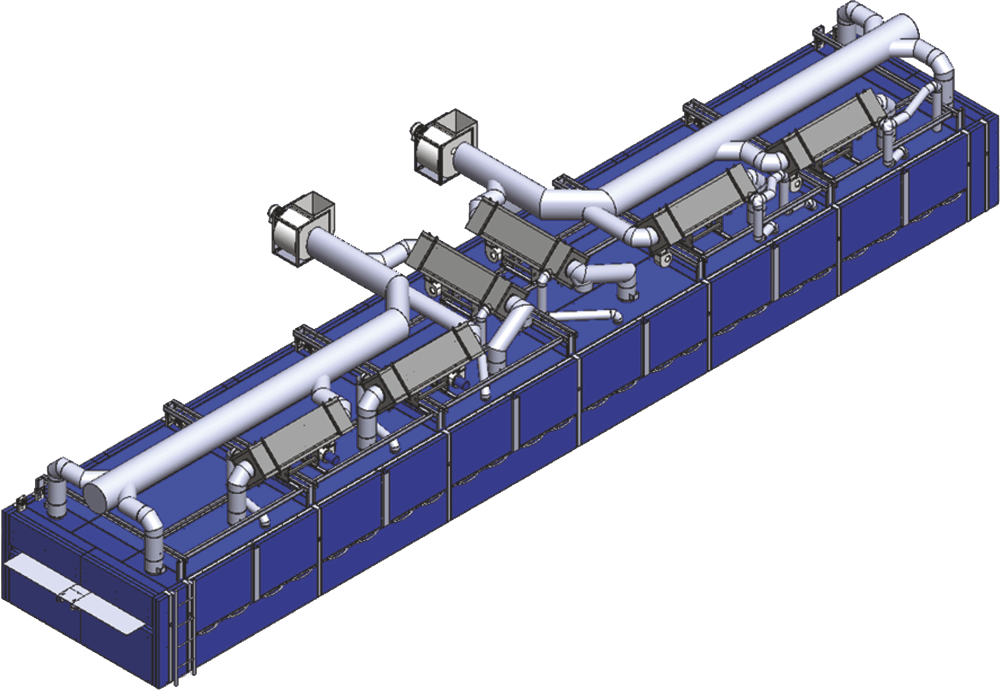

HRU installation with external ducting

Cleaning of HRUs

HRU cleaning

Saving / ROI