Engineering Services: Transforming Data, Empowering Innovation

InspirOn Engineering Services delivers comprehensive, end-to-end engineering solutions for diverse industries worldwide. We leverage our deep engineering and manufacturing expertise to provide precise, cost-effective designs.

Our services empower engineering and manufacturing companies to enhance product quality, cost-efficiency, Time to Market and ultimately adding significant value to their offerings.

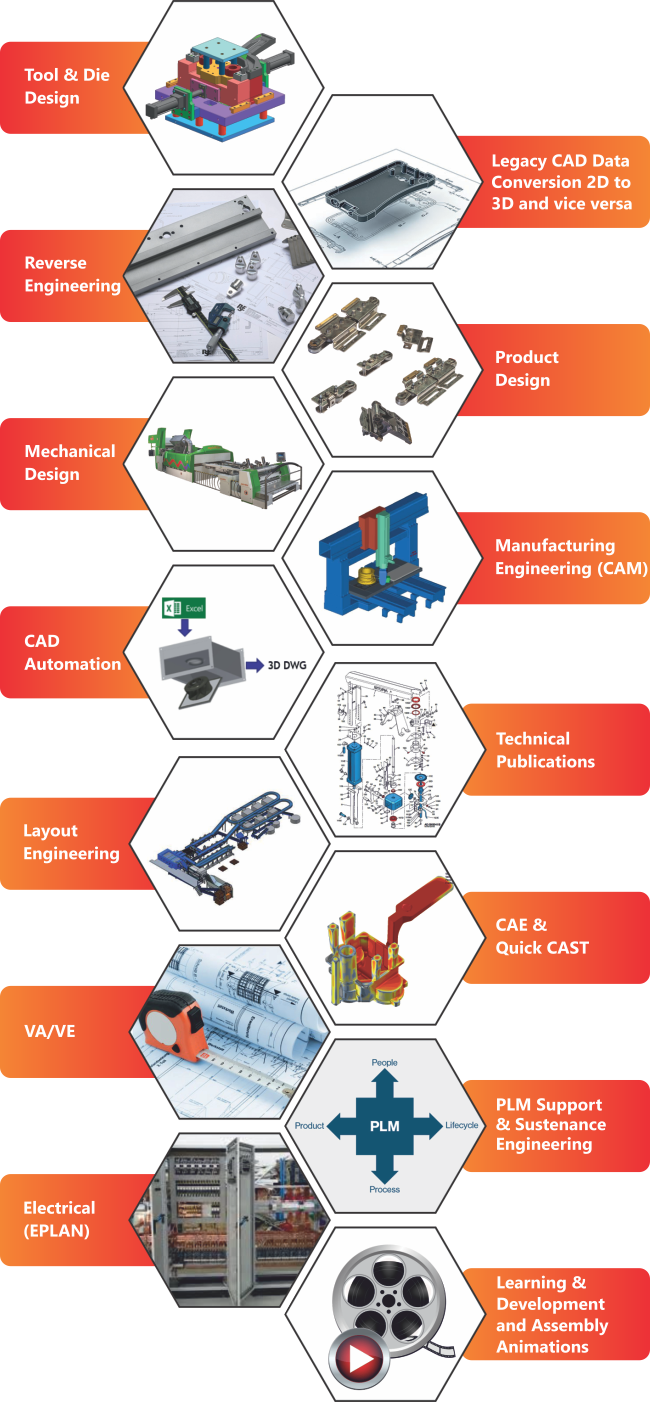

Area of Services:

- Mechanical engineering

- Product development

- Value analysis and Value Engineering (VAVE)

- Tooling solutions

- Legacy data conversion 3D & 2D

- PLM / PDM support

- Localization

- Prototyping & Validation

- Electrical engineering

- Product configurator

- Should costing

- CAM Programming / Manufacturing Solutions

- CAD Automation

- Rendering & Animations

- FEA & CFDs

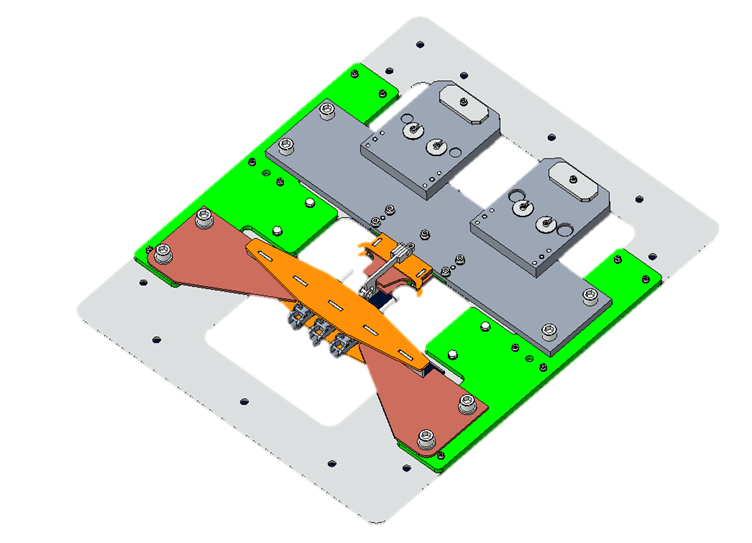

- Fixture Design

Computer Aided Design - CAD

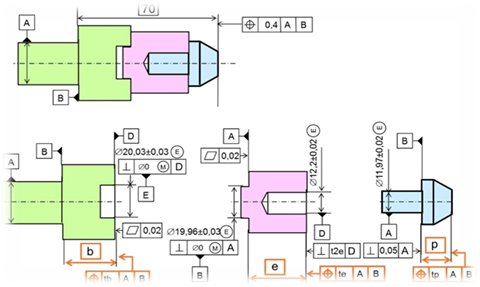

Legacy Data Conversion (2D to 3D and vice versa)

2D to 3D Conversion:

Transform your existing 2D drawings into detailed 3D models. This service enhances visualization, allowing for better analysis and presentation of designs.

3D to 2D Conversion:

Convert 3D models into precise 2D drawings for documentation, manufacturing, and compliance purposes. This ensures that all aspects of the design are accurately captured and easily accessible.

Reverse Engineering

Recreate CAD Models:

We Generate accurate CAD models from existing physical products. This service is ideal for redesigning, improving, or replicating parts and products.

Component Analysis:

Analyze and document the design and functionality of existing components. This helps in understanding the product's structure and identifying areas for improvement.

Product Customization

Tailored Design Solutions:

We customize products to meet specific client requirements. This includes modifying existing designs or creating new ones to enhance functionality, aesthetics, and user experience.

Prototype Development:

We develop prototypes based on customized designs to test and validate the product before full-scale production.

Product Standardization

Consistency and Compliance:

We standardize products to ensure consistency in design and manufacturing. This service helps in maintaining quality and meeting industry standards.

Documentation and Guidelines:

We create detailed documentation and guidelines for standardized products, ensuring that all stakeholders have clear and consistent information.

Reverse Engineering

Concept to Engineering Design:

We transform your ideas into detailed engineering designs, ready for manufacturing.

Geometric Dimensioning and Tolerances:

We ensure precise measurements and tolerances in your designs.

CAD Automation Solutions:

We implement automation in your CAD processes to enhance efficiency and accuracy.

Product Design and Development:

Creating innovative and functional product designs from concept to final engineering.

Developing parametric models for easy modifications and updates.

Ensuring precise measurements and tolerances in designs.

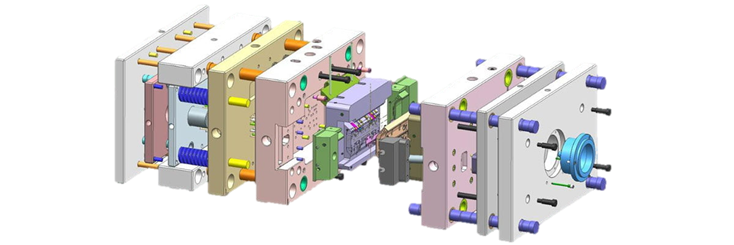

Manufacturing Engineering:

Computer Aided Manufacturing (CAM Programming) – Up to 5 Axis

CNC Program Generation:

We create CNC programs for up to 5-axis machines, ensuring precise and efficient manufacturing.

Tool Paths Verification:

We use simulation tools to verify tool paths and optimize machining processes

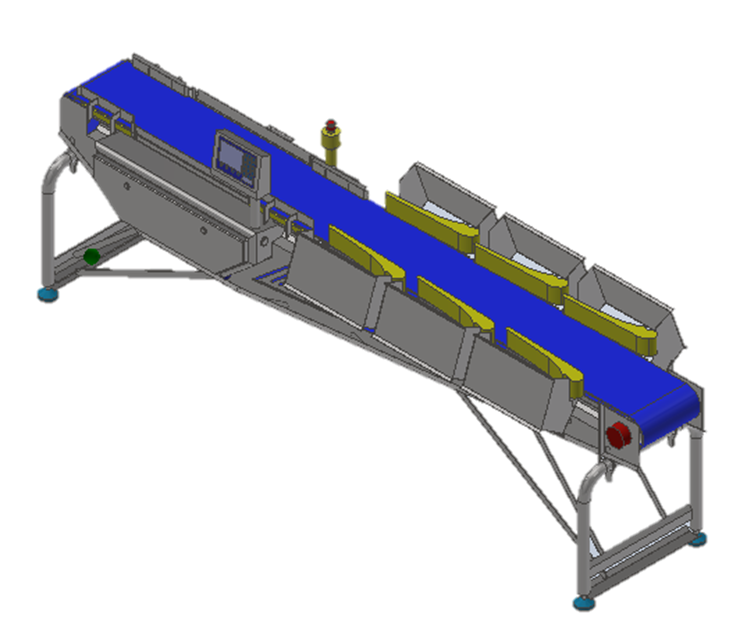

Tooling solutions

We provide precision engineering solutions with our expert Tool and Die Design services. Utilizing advanced CAD/CAM software, we create highly accurate molds, dies, and tools tailored to your specific manufacturing needs. Whether for custom tooling or mass production, our services ensure exceptional quality and efficiency in every project.

Fixture Design

We specialize in designing custom fixtures that meet your specific production and assembly needs. Our designs are aimed at improving efficiency and accuracy in your processes. Easy to use, also durability and reliability.

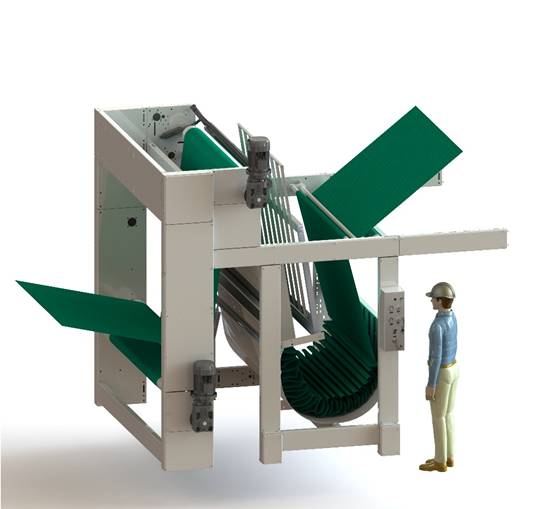

Plant Layout Engineering:

3D Visualization of Factory Assets

Create detailed 3D visualizations of all machine modules and factory assets.

Creating 3D visualizations of factory assets and machine modules.

Developing layouts for efficient workflow and space utilization.

Providing detailed project engineering for process engineering layouts.

Project Engineering Estimation Layouts

We develop layouts for accurate project engineering estimations.

Detailed Process Engineering Layouts

We provide detailed layouts for process engineering, ensuring efficient workflow and space utilization.

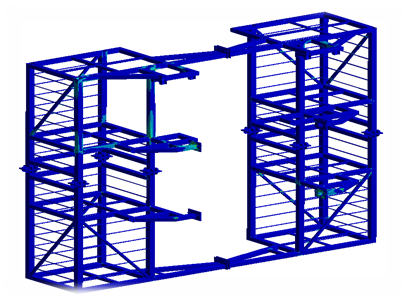

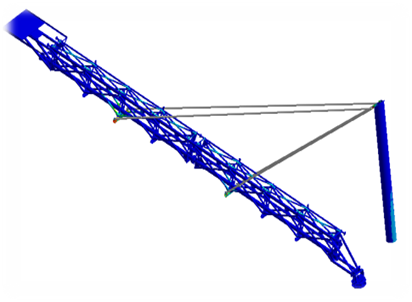

Computer Aided Engineering (CAE)

Finite Element Analysis (FEA):

We perform static structural and dynamic analysis for linear and non-linear structures, including vibration analysis.

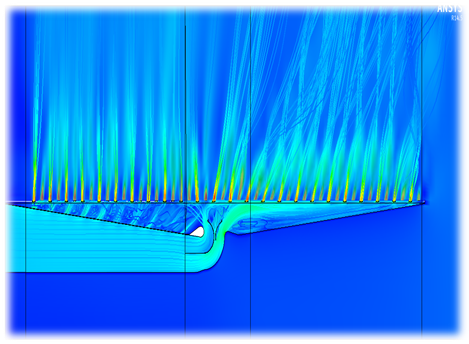

Computational Fluid Dynamics (CFD):

We conduct fluid flow simulations for steady and unsteady flows, as well as casting flow simulations.

Other Engineering Services

Engineering Change Management Support (ECO / ECN):

We provide Engineering Change Order work directly to your network via PLM, ensuring seamless change management.

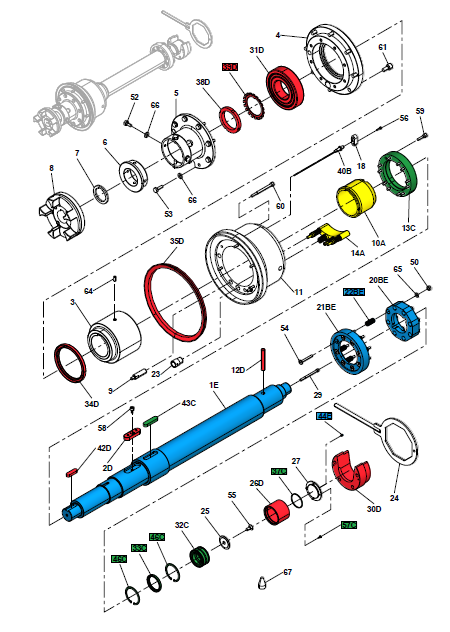

Technical Publications:

We create service and maintenance manuals with exploded views and color codes using Visual Enterprise Author software.

Value Engineering:

We enhance product quality and reduce costs through design optimization and value engineering services.

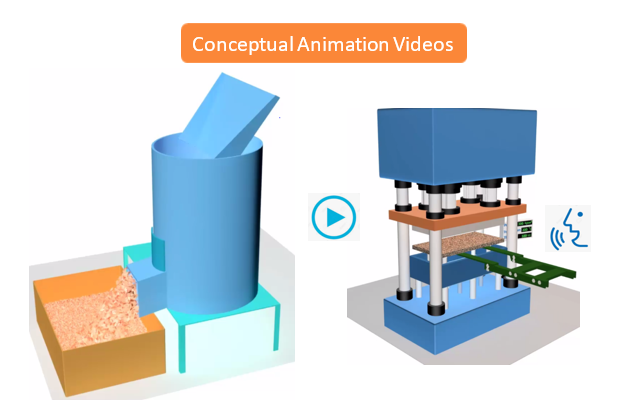

Animation and Visualization Services:

We produce animations to showcase the working of mechanisms or process line concepts, aiding in customer presentations.

Training Material Creation:

We develop training material videos with voice-over to assist in educating your team or customers.