About Us

Pioneering Engineering Excellence Since 1973

InspirOn Engineering Private Limited (IEPL), established in 1973, is a global leader in precision engineering solutions. The company is the world’s largest manufacturer of high-performance aluminium flyers, having produced and sold over 5 million units worldwide under the renowned InspirOn Flyer brand. Alongside its dominance in textile flyers, IEPL has a strong presence in textile finishing equipment, aluminium die casting & precision components and engineering services.

With state-of-the-art CNC machining, non-ferrous casting capabilities, and advanced engineering expertise, IEPL serves a diverse range of industries, including textile machinery, automotive manufacturing, and precision engineering. The company exports over 35% of its flyers to OEMs in Germany, Italy, and Spain, while also meeting global replacement demands across Argentina, Bangladesh, China, Egypt, Greece, Indonesia, Iran, Malaysia, Mexico, Nepal, Nigeria, Pakistan, Peru, Philippines, Portugal, South Africa, Sri Lanka, Thailand, Turkey, Taiwan, the United States, Vietnam, and Zimbabwe. IEPL is ISO 9001:2015 & ISO 14001:2015 certified for the design, development and manufacturing of its high-precision products. Recently, we have obtained of IATF 16949:2016.

Our Four Lines of Business

1. Textile Flyers – Precision Components for the Global Textile Industry

IEPL is the world’s largest manufacturer of high-performance aluminium flyers, a critical component in textile spinning machinery. With over five decades of expertise, the company continues to be the preferred supplier for both OEMs and global replacement markets, ensuring superior durability, precision and efficiency.

2. Textile Finishing Equipment – Innovation in Stenter Technology

IEPL has developed cutting-edge textile finishing solutions, including the Motex Stenter for the domestic market and the SprintOn Stenter for international markets. These finishing lines, consisting of a padder and stenter, are designed with an energy-efficient hot air distribution system that enhances heat transfer while reducing downtime and maintenance costs. The structural configuration of these stenters ensures optimal performance and reliability, making them a preferred choice among quality-conscious textile manufacturers.

3. Aluminium Die Casting & Precision Components – High-Performance Industrial Solutions

IEPL has state-of-the-art non-ferrous casting capabilities, producing precision components for multiple industries, including textile machinery and automotive manufacturing. The company also manufactures pins, clips, and chains for stenter frames, which are essential for textile finishing processes. With expertise in CNC machining, IEPL ensures that all components meet stringent quality and performance standards.

Additionally, IEPL offers contract manufacturing solutions, leveraging its modern sheet metal fabrication, CNC machining, and non-ferrous foundry infrastructure. By providing end-to-end manufacturing services, IEPL serves as a trusted partner for European and US-based engineering industries, delivering high-quality, precision-engineered products.

4. Engineering Services – Comprehensive Design & Development Solutions

IEPL provides engineering design, tool development, and precision engineering services, supporting industries in achieving highperformance manufacturing capabilities. With expertise in CAD modeling, simulation, and process optimization, IEPL helps clients improve product efficiency and manufacturability. The company’s advanced engineering solutions ensure that offshore customers receive tailored, high-quality designs that meet global industry standards.

Registered Office & Unit-1 (Odhav)

Registered Office & Unit-1 (Odhav)

Unit-2 (Chandial)

Unit-2 (Chandial)

Mission

We are a customer - oriented company who will deliver products / services of the best quality, appropriate technology and world class services, which meet - and preferably surpass - customer expectations.

We shall strive to attain and retain market leadership in each field of our business activities, provide a challenging, fair and fulfilling work environment, operate in an environment - friendly manner with a social conscience, provide our stake - holder's adequate returns.

Vision

To create, enhance and innovate the value proposition for glocal customers by exploring existing and emerging business opportunities aligned to core ideologies.

Vision for each Strategic Business Unit

-

Textile Flyer

To be a glocal leader for flyer

-

Hot Air Stenter

To be an optimized solution provider for Stenter in glocal markets, in terms of value proposition and price performance

-

Aluminium Die Casting

To be a strategic sourcing partner offering precision engineered solutions covering concept to calibration for glocal customers

-

Engineering Services

We lead the Engineering Solutions Industry by helping our customers develop best quality innovative products, with optimum time to market.

State-of-the-Art Manufacturing Facilities

In 2020, IEPL expanded its operations with the establishment of a new casting manufacturing facility (Unit-2) at Chandial, Ahmedabad. Spread over 28,500 sq. meters and located 22 km from the Odhav plant, this greenfield facility is designed on lean manufacturing principles. Equipped with advanced machinery, automation, and modern technology, it enhances production capacity, efficiency, and scalability, ensuring IEPL remains at the forefront of engineering innovation.

With a strong commitment to quality, innovation, and global leadership, IEPL continues to drive excellence across industries, setting new benchmarks in engineering and manufacturing solutions.

Core Values and Beliefs

At InspirOn we pursue timeless core values and beliefs

On the one hand

- Purpose beyond profit

- Clear vision and sense of direction

- Selection of employees steeped in the core

- Ideological control

- Organization aligned with core ideology

- Investment for the long term

On the other hand

- Pragmatic pursuit of profit

- Opportunities groping and experimentation

- Selection of employees that induce change

- Operational autonomy

- Organization adapted to its environment

- Demands for short-term performance

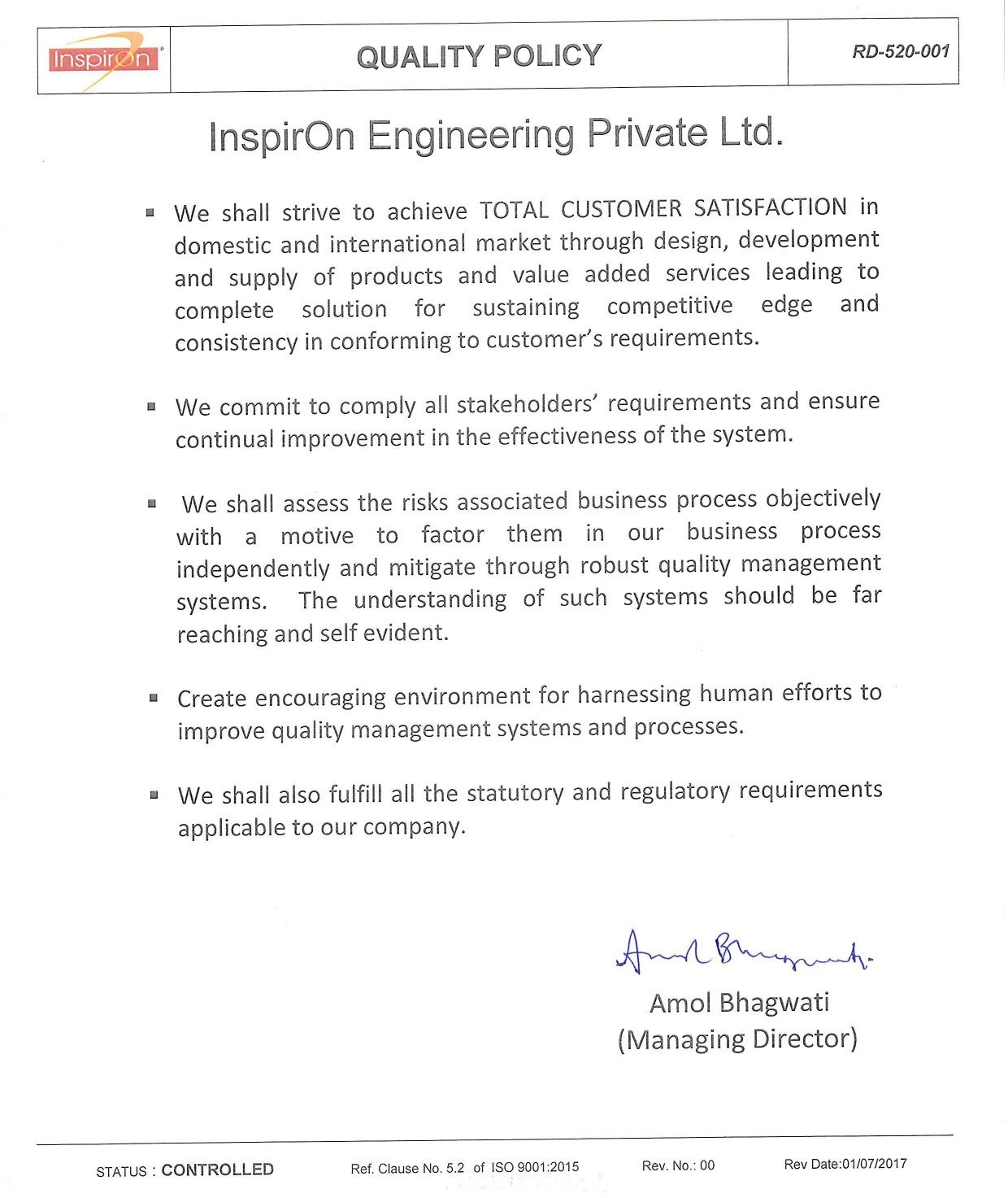

Our Commitment to Quality and Excellence

At InspirOn, we strive to deliver the highest standards of quality and customer satisfaction. We ensure timely project completion, cost-effectiveness, and efficient use of resources. By closely monitoring reliability metrics like Mean Time Between Failure (MTBF) and Mean Time To Repair (MTTR), we enhance operational efficiency. Our proactive approach to customer complaints helps us improve continuously. We also focus on reducing internal defects and maintaining consistency in quality. To achieve excellence, we invest in employee training and development, ensuring continuous learning and skill enhancement.

Safety Health and Environment (SH&E) Policy

We shall strive to:

Take actions on a continuous basis in order to create conditions at our workplace, which will prevent accidents and illness, thereby effectively integrating safety in all our business areas. Provide a safe and healthy working environment and operate in a manner that will safeguard all employees and protect the environment and natural resources. Also, build in a system to use to the extent possible material/s on recycling concept like water etc.

Identify hazards, assess and control risk to safety, health and environment to which employees and others may be exposed. Prevent / minimize pollution, occupational illnesses and safety risks through continuous improvements in process and practices, effective risk management and mitigation.